2.8-Ton Compact Crawler Mini Excavator

2.8-Ton Compact Crawler Excavator | Superior Performance

The KAISAN KN28 is a high-performance 2.8-ton mini excavator powered by a durable Kubota D1105 diesel engine, generating 14 kW to handle challenging operations in tight spaces. With a maximum excavation depth of 2830 mm and a working radius of 4290 mm, it comes standard with a 0.1 m³ bucket. Its hydraulic system integrates an efficient variable displacement piston pump that delivers 61.6 L/min for precise and smooth control.

The machine is available with either rubber or steel track options and includes a 23-liter fuel tank for longer working cycles. Engineered for easy maintenance, the KN28 delivers consistent reliability and cost-effective performance, making it ideal for construction, landscaping, and utility applications.

The KN28 Crawler Excavator from Shandong Kaisan Machinery Co., Ltd. is built to excel in tight spaces, offering a versatile mix of compact design and powerful performance. Delivering 14 kW (2200 rpm) and 51.9 N·m of torque, its reliable Kubota D1105 engine drives a high-efficiency hydraulic system. This system features a variable piston pump that delivers 61.6 L/min flow at 20.5 MPa for smooth and precise operation. With an operating weight of 2750 kg and a 0.1 m³ standard bucket, it delivers a maximum digging depth of 2830 mm and a dumping height of 3005 mm. The machine's compact profile (2480 mm height, 4195 mm transport length) and low ground pressure (24 kPa) from its track options enhance on-site efficiency. Supported by a 23L fuel tank, the KN28 is perfectly suited for urban construction, landscaping, and various light industrial duties.

Specification

Model | KN28 | |

Manufacturer | SHANDONG KAISAN MACHINERY CO.,LTD | |

Brand | KAISAN | |

Operating Weight | 2750kg | |

Overall dimension | 4195x1550x2480mm | |

Bucket capacity | 0.1cbm | |

Engine type | KUBOTA D1105 | |

Rated power/speed | 14kw/2200rpm | |

Voltage of start motor | 12V | |

Starting type | ELECTRIC | |

Traveling speed | 2.6/4.5 km/h | |

Maximum Grade ability | 58%(30°) | |

Ground pressure | 24Kpa | |

Maximum Bucket digging force | 23.5Kn | |

Maximum Arm digging force | 14Kn | |

Hydraulic system pressure | 20.5Mpa | |

Hydraulic flow | 61.6L/min | |

Boom length | 2200mm | |

Arm length | 1300mm | |

Fuel tank capacity | 23L | |

Hydraulic oil tank capacity | 24L | |

Length of rubber track | 1565mm | |

Track gauge | 1670mm | |

Minimum Ground clearance | 286mm | |

Swing radius at tail | 860mm | |

Height of blade | 308mm | |

Maximum Digging height | 4427mm | |

Maximum Dumping height | 3005mm | |

Maximum Digging depth | 2830mm | |

Maximum Vertical digging depth | 2530mm | |

Maximum Digging distance | 4835mm | |

Maximum Lifting height of blade | 308mm | |

Maximum Cutting depth of blade | 363mm | |

Boom swing angle(Left/Right) | 69°/ 45° | |

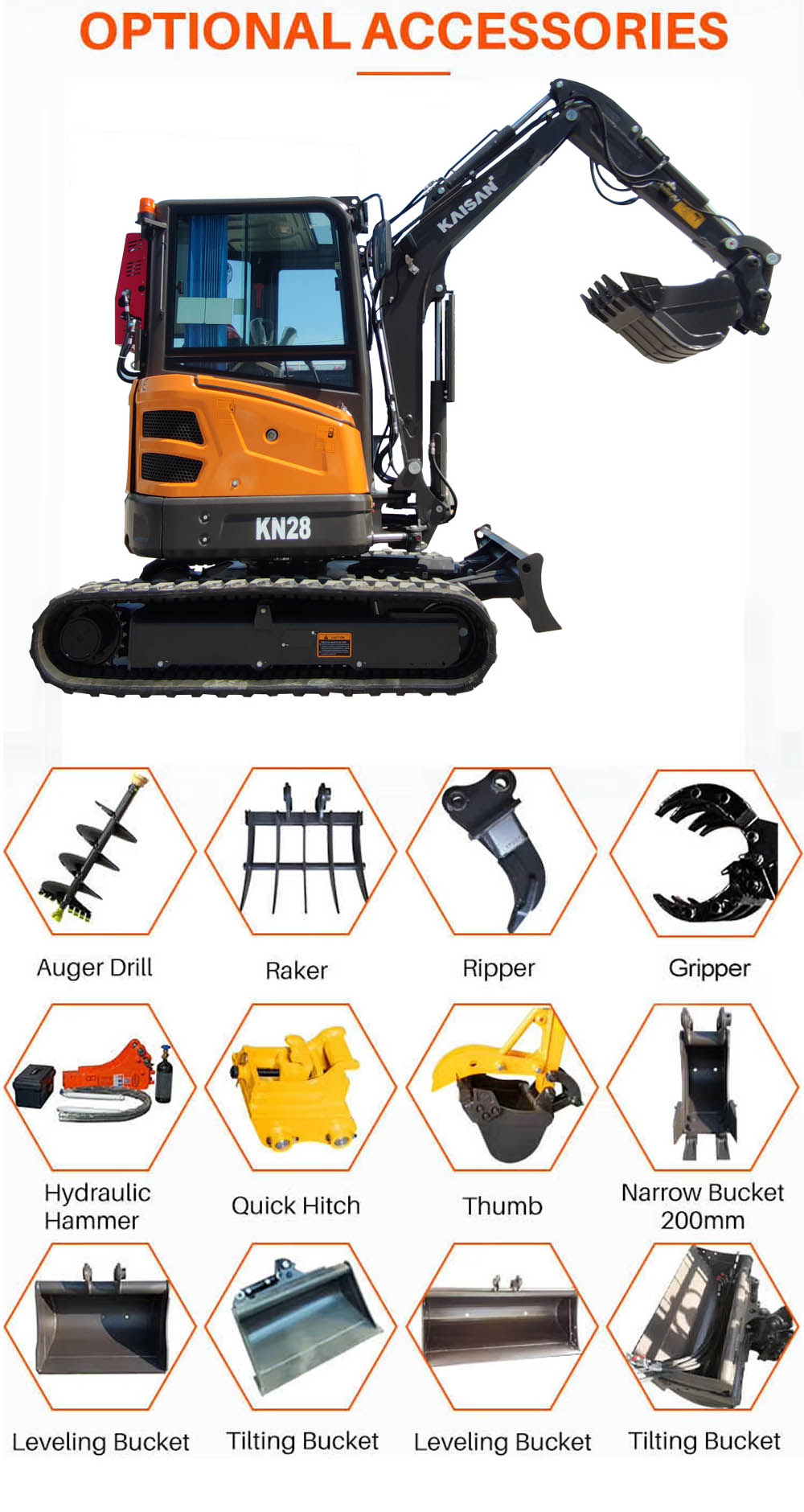

Product Description

Packing & Delivery

Company Profile

Company Overview

With two decades of industry experience, we have established ourselves as a leading provider of powerful and efficient construction equipment. Our diverse portfolio serves a worldwide clientele in over 50 nations with wheeled excavators (5-12t), crawler excavators (0.8-12t), and compact dumpers. Each product meets CE and ISO requirements, affirming our dedication to superior safety and robust performance. The synergy between our expert engineering workforce and advanced manufacturing technology enables rigorous quality assurance. By utilizing premium-grade parts, we design our machinery for longevity and reduced service needs, ensuring they deliver sustained productivity in challenging conditions, from construction sites and landscaping projects to various industrial operations.

Exhibition

Our Service

1.Warranty Coverage We provide a comprehensive and transparent warranty policy that covers major components, including the engine and hydraulic system, ensuring peace of mind from the start.

2.Scheduled Maintenance Intervals

Our service plans are based on rigorous operating hour milestones (e.g., 50, 250, 500, 1000 hours), covering essential checks like engine oil changes, hydraulic filter replacements, and track tension adjustments.

3.Global Parts & Technical Support With a presence in over 50 countries, we maintain a global network for genuine spare parts. Our technical support team is available to assist your local mechanics with complex diagnostics and repair procedures.

4.On-Site Inspection & Diagnostics

We offer professional on-site inspection services to perform thorough machine health assessments, identify potential issues early, and provide accurate diagnostics to minimize downtime.

5.Operator & Technician Training We conduct specialized training programs covering safe machine operation, daily pre-start checks, basic troubleshooting, and advanced maintenance practices to maximize machine longevity and jobsite safety.

FAQ

Q: What is the main advantage of a mini excavator like the KN28? A:Its compact size and low ground pressure allow it to work efficiently in confined spaces where larger machinery cannot operate, such as urban construction sites and indoor projects.

Q: Why is the Kubota engine highlighted? A: Kubota diesel engines are renowned for their high reliability, fuel efficiency, and low emissions, ensuring powerful performance and lower long-term operating costs.

Q: What is the benefit of a variable displacement piston pump? A: It automatically adjusts hydraulic flow to match demand, leading to smoother operation, significantly better fuel economy, and less system heat compared to a fixed pump.

Q: What do the CE and ISO certifications mean? A: They guarantee the machine meets rigorous international standards for safety, quality, and environmental impact, ensuring a reliable and certified product for global markets.

Q:What is the typical fuel consumption? A: While it varies with workload, the efficient engine and 23L tank typically support a full 8-10 hour shift on one tank, ensuring high productivity.