2.8 Ton Mini Crawler Excavator High Quality

A 2.8-ton compact excavator featuring a dependable 14 kW Kubota diesel engine

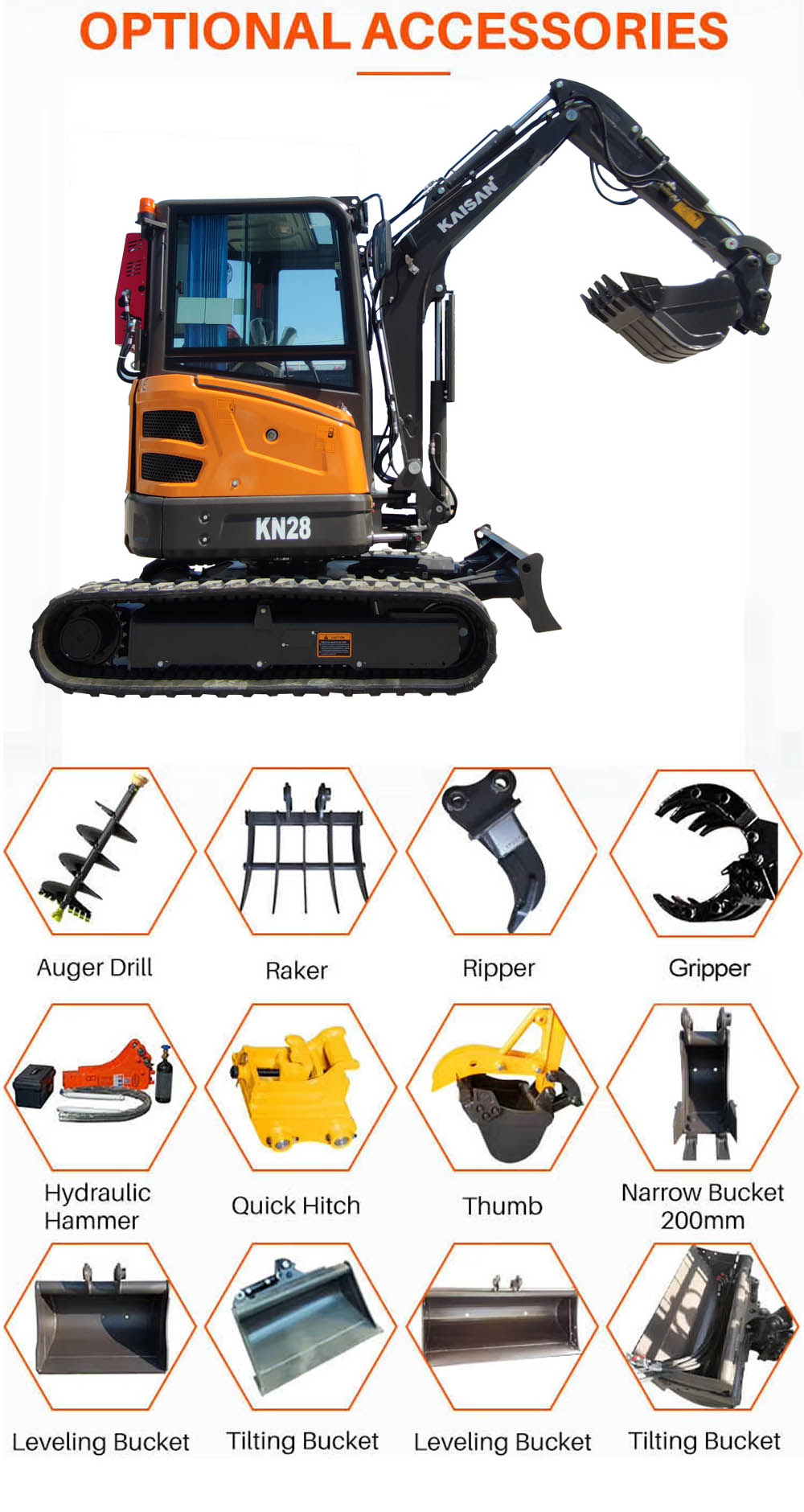

The KAISAN KN28 is a small-sized 2.8-ton mini excavator equipped with the robust Kubota D1105 diesel engine, delivering 14 kW of power for demanding tasks in confined areas. It achieves a digging depth of 2830 mm and a working reach of 4290 mm, paired with a standard 0.1 m³ bucket. The hydraulic system incorporates a high-efficiency variable piston pump supplying a flow rate of 61.6 L/min for responsive and smooth operation. Available with either rubber or steel tracks, the machine includes a 23-liter fuel tank to support extended operation periods. Designed for straightforward maintenance, the KN28 is suited for construction, landscaping, and utility projects, offering long-term reliability and economical performance.

Engineered for superior performance in tight spaces, the KN28 Crawler Excavator from Shandong Kaisan Machinery Co., Ltd. delivers a powerful blend of compactness and capability. Its Kubota D1105 powerplant generates 14 kW (2200 rpm) and 51.9 N·m of torque, driving a high-efficiency variable piston pump system (20.5 MPa, 61.6 L/min) for responsive hydraulics. With an operating weight of 2750 kg and a standard 0.1 m³ bucket, key metrics include a 2830 mm maximum digging depth, 3005 mm max dumping height, and a 4.5 km/h travel speed. The unit's limited overall height (2480 mm) and transport length (4195 mm) ensure excellent maneuverability. Suitable for rubber or steel tracks (ground pressure: 24 kPa) and featuring a 23L fuel tank, the KN28 is ideal for urban construction, landscaping, and light industrial duties.

Specification

Model | KN28 | |

Manufacturer | SHANDONG KAISAN MACHINERY CO.,LTD | |

Brand | KAISAN | |

Operating Weight | 2750kg | |

Overall dimension | 4195x1550x2480mm | |

Bucket capacity | 0.1cbm | |

Engine type | KUBOTA D1105 | |

Rated power/speed | 14kw/2200rpm | |

Voltage of start motor | 12V | |

Starting type | ELECTRIC | |

Traveling speed | 2.6/4.5 km/h | |

Maximum Grade ability | 58%(30°) | |

Ground pressure | 24Kpa | |

Maximum Bucket digging force | 23.5Kn | |

Maximum Arm digging force | 14Kn | |

Hydraulic system pressure | 20.5Mpa | |

Hydraulic flow | 61.6L/min | |

Boom length | 2200mm | |

Arm length | 1300mm | |

Fuel tank capacity | 23L | |

Hydraulic oil tank capacity | 24L | |

Length of rubber track | 1565mm | |

Track gauge | 1670mm | |

Minimum Ground clearance | 286mm | |

Swing radius at tail | 860mm | |

Height of blade | 308mm | |

Maximum Digging height | 4427mm | |

Maximum Dumping height | 3005mm | |

Maximum Digging depth | 2830mm | |

Maximum Vertical digging depth | 2530mm | |

Maximum Digging distance | 4835mm | |

Maximum Lifting height of blade | 308mm | |

Maximum Cutting depth of blade | 363mm | |

Boom swing angle(Left/Right) | 69°/ 45° | |

Product Description

Packing & Delivery

Company Profile

Company Profile

For over two decades, we have been a premier producer of high-performance construction equipment. Our core product range encompasses wheeled excavators (5-12t), crawler excavators (0.8-12t), and compact dumpers, serving clients in over 50 countries worldwide. These machines hold CE and ISO certifications, reflecting our adherence to rigorous global standards for safety and durability. Supported by a dedicated engineering team and advanced manufacturing infrastructure, we enforce stringent quality assurance protocols to ensure exceptional reliability. Our equipment is engineered with premium components for reduced maintenance and long operational life, delivering consistent productivity in demanding environments such as construction, landscaping, and various industrial sectors.

Exhibition

Our Service

1.Daily/Pre-Start Checks (Before each shift) Check and verify engine oil, coolant, and hydraulic fluid levels.Inspect the undercarriage (tracks or wheels) for proper tension and clear any debris and so on.

2.Scheduled Periodic Maintenance

Engine Oil & Filter: Replace every 250-500 operating hours, depending on workload and conditions.Hydraulic Oil Filter(s): Replace every 500 hours to maintain system cleanliness and performance.

3.Long-Term Service Intervals Hydraulic Oil: Complete oil change is recommended every 2000-3000 operating hours.Coolant: Replace engine coolant according to the manufacturer's schedule, typically every 2 years or 4000-6000 hours.

4.Key Service Recommendations

Consult the Official Manual: Always prioritize the specific intervals and procedures outlined in the official KAISAN KN28 Operation and Maintenance Manual Use Genuine Parts: For optimal reliability and compatibility, use KAISAN-approved or OEM (Original Equipment Manufacturer) parts and fluids.

5.Safety First Always perform service on a firm, level surface with the engine OFF and the key removed.Lower all attachments (e.g., the bucket) completely to the ground to release hydraulic pressure before starting any work.

FAQ

Q: What tracks does the KN28 support?

A:The KN28 can be equipped with either rubber or steel tracks, and this is customizable from the OEM.

Q: What is the manufacturer's warranty?

A: The machine comes with a standard warranty of 1 year or 2,000 operating hours, whichever occurs first. The manufacturer also mentions that extended support plans are available after the warranty period expires

Q: What is the Minimum Order Quantity (MOQ)?

A: The MOQ is 1 unit, and discounts are available for bulk orders

Q: What is the production lead time?

A: For standard models, the lead time is 7 to 10 days after deposit. For customized orders, the lead time is 15 to 25 days

Q:What payment terms are accepted?

A: The manufacturer accepts T/T (Bank Transfer) and L/C (Letter of Credit).