KN80-9: 8 Ton Crawler Excavator Made in China with Reliable Quality

Shandong KAISAN Machinery Co., Ltd.'s KN80-9 crawler excavator, an 8-ton model, boasts powerful performance and high efficiency, boasting a sophisticated design. Equipped with a powerful 54.3 kW/2200 rpm imported YANMAR (4TNV98T) engine, it ensures robust performance and high efficiency. The advanced German INLINE hydraulic system ensures precise and stable operation, while its powerful digging force ensures efficient operation. With a maximum digging depth exceeding 4 meters and a working radius approaching 6.2 meters, the KN80-9 easily handles a variety of tasks. Striving to provide a comfortable working environment and ensure mechanical durability, it is equipped with world-class, high-quality components and comes standard with air conditioning.

![8Ton New Household Precision Customizable Excavator 8Ton New Household Precision Customizable Excavator]()

Model | KN80-9 |

Manufacturer | SHANDONG KAISAN MACHINERY CO.,LTD |

Brand | KAISAN |

Operating Weight | 8500kg |

Overall dimension | 6100x2300x2680mm |

Bucket capacity | 0.34cbm |

Engine |

Engine type | YANMAR(4TNV98T) |

Rated power/speed | 54.3kw/2200rpm |

Voltage of start motor | 12V |

Starting type | ELECTRIC |

Hydraulic system |

Hydraulic main pump | Germany INLINE |

Hydraulic system pressure | 24.5MPa |

Hydraulic system flow | 165L/Min |

Pilot pump | Germany INLINE |

Pilot pump max flow | 9L/Min |

Valve | Germany INLINE |

Swing motor | Germany INLINE |

Max swing speed | 10r/min |

Travel motor | EDDIE |

Max travel speed | 5.1km/h |

Sealing parts | USA PARKER |

Gear | high 5.17km/h, low 2.7/km/h |

Bucket dimension(length*width*depth) | 760*660*460 |

No. of teeth | 5 |

Bucket Digging Force | 52Kn |

Arm Digging Force | 64Kn |

Grade ability | 70 Degree |

Tanks |

Working fuel consumption | 6.58L/h |

Fuel tank capacity | 130L |

Engine oil tank capacity | 11L |

Hydraulic oil tank capacity | 90L |

Cooling fluid tank capacity | 20L |

Overall size |

Shipping Length | 6100mm |

Shipping Height | 2680mm |

Shipping Width | 2300mm |

Boom length | 3710mm |

Arm length | 1650mm |

Radius,Swing Center to Rear End | 1755mm |

Count weight height | 1685mm |

Count weight ground clearance | 760mm |

Ground clearance | 380mm |

Blade height | 360mm |

Track length on the ground | 2150mm |

Length of two tracks | 1700mm |

Track shoe width | 450mm |

Operating range |

Max Digging Height | 7165mm |

Max Dumping Height | 5065mm |

Max Digging Depth | 4035mm |

Max Digging Radius | 6180mm |

Standard machine with A/C | AC |

![8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct 8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct]()

![8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct 8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct]()

More Products

![8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct 8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct]()

![8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct 8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct]()

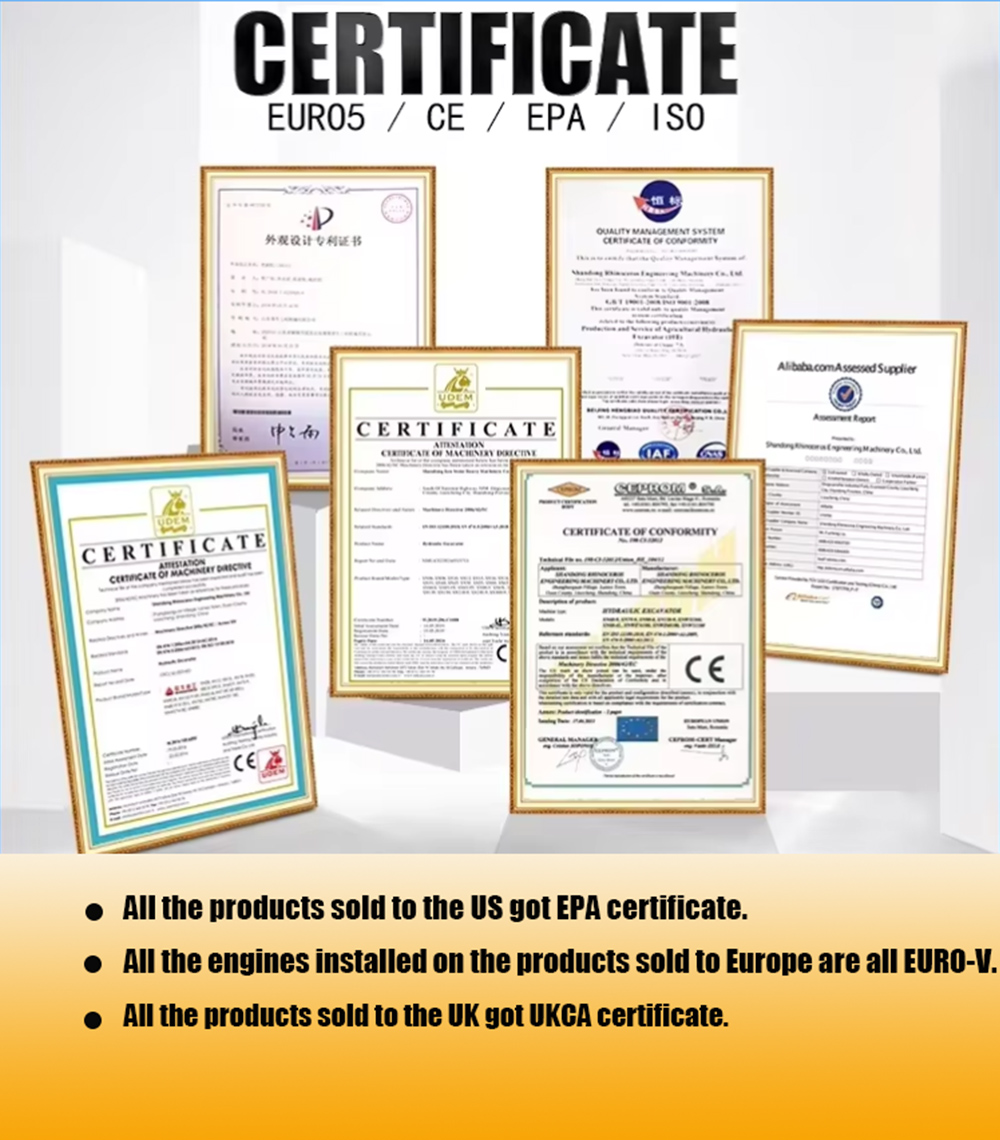

KAISAN Group leverages its deep engineering expertise to ensure that every machine line is manufactured to the highest standards. Our focus on safety and reliability has established us as an industry leader. Through advanced automated processes, we improve structural weld integrity by 40%. With an annual production capacity of 800 units, all CE Stage V/Euro V-compliant equipment enables rapid delivery to customers worldwide.

![8Ton New Household Precision Customizable Excavator 8Ton New Household Precision Customizable Excavator]()

![8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct 8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct]()

![8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct 8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct]()

![8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct 8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct]()

![8Ton New Household Precision Customizable Excavator 8Ton New Household Precision Customizable Excavator]()

Efficient Maintenance and Technical Support Services

Our dedicated maintenance team ensures prompt response to equipment failures and provides expert technical support.

Proactive Maintenance Service Program

Using specialized diagnostic tools, we conduct regular equipment health checks and provide preventive maintenance recommendations to identify potential issues early.

Reliable Parts Supply and Logistics

Leveraging our local and regional dealer network, we ensure a stable supply of commonly used parts and significantly shorten spare part lead times.

Cost-Effective Parts Replacement Solutions

Our trade-in program for worn parts helps customers reduce maintenance costs and extend equipment life.

Minimizing Downtime

With our flexible supply chain and inventory management, we effectively prevent production interruptions and ensure continuous and stable equipment operation.

Systematic Customer Training Services

We offer training courses covering safe operation and energy-saving techniques, especially for new equipment users.

Daily Maintenance Guidance and Support

Our expert team assists customers with routine maintenance, reducing the need for non-fault-related repairs and improving overall equipment reliability.

![8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct 8.5 Ton Crawler Excavator Equipped Wood Clamp Factory Direct]()

Q: How do I choose the right excavator for my needs?

A:When selecting an excavator, you should comprehensively evaluate multiple factors, including your actual operating requirements, engine power, attachment compatibility, equipment durability, and after-sales service. Combining these factors with specific project requirements can maximize operational efficiency and achieve optimal cost-effectiveness.

Q: What are the advantages of choosing a domestic excavator?

A: Domestic excavators generally offer a higher price-performance ratio, more economical maintenance costs, a broad and convenient parts supply system, and responsive after-sales support. These features make them an ideal choice for many users who need to strike a balance between performance and economy.

Q: How can I operate an excavator efficiently?

A:To improve fuel economy, avoid idling for extended periods, plan your work routes to minimize wasted movement, and actively enable energy-saving modes when applicable to reduce overall fuel consumption.

Q: How can I prevent my excavator from slipping when operating on a slope?

A: During operation, keep the bucket low to lower the center of gravity, avoid sharp turns or sudden movements, and keep the tracks perpendicular to the slope as much as possible to enhance overall machine stability and prevent skidding.

Q: What should I do if the excavator suddenly stops during operation?

A:We recommend first checking basic items such as the fuel level and electrical fuses. If this fails to resolve the issue, further troubleshoot the hydraulic system and related sensors. Refer to the equipment manual for troubleshooting assistance or contact professional technical support for assistance.