Compact Wheeled Digger 8 Ton CE Certified

1. Powered by a Yanmar turbocharged engine - globally renowned for superior torque output, 15% improved fuel efficiency, and noise reduction technology. Delivers reliable performance across demanding working conditions.

2. Intelligent hydraulic system integrates Kawasaki pumps and Parker valves, achieving 22% energy savings. Features precision flow control with 0.5s response time and minimized pressure loss for sustained excavation power.

3. Multi-layer cooling architecture utilizes Donaldson radiators with vortex airflow design. Maintains optimal 85-95°C operating temperature range through enhanced heat dissipation efficiency.

4. Robotic welding (FANUC) with 100% UT testing on structural components. Reinforced X-frame design demonstrates 35% higher fatigue resistance than industry standards.

5. ISO-certified operator cabin with 3D suspension system reduces vibration by 40%. Features climate control (5-35°C adjustable) and 68dB noise insulation for all-day comfort.

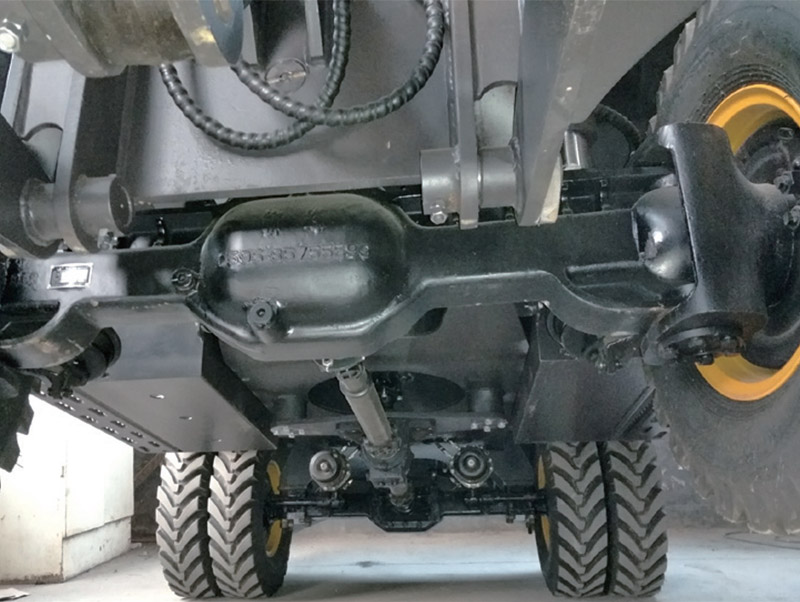

Wheel Excavator KN90-Y

Specifications:

Weight: 8,300 kg

Engine: Japan YANMAR 4TNV98, 46.3 kW

Key Features:

Powered by YANMAR four-cylinder engine , it achieves 18% greater torque density (Max torque 223.3-243.5N.m) with Low operational noise levels, 15% improved fuel efficiency, and military-grade durability verified in 2,000-hour extreme condition testing.

Rexroth Hydraulic System:

The multi-pump synergy technology of Rexroth of Germany is adopted to realize efficient conversion of engine power through intelligent flow distribution. The system shows stable output capacity in heavy-load operation, taking into account high-intensity operation requirements and energy-saving performance, and with the adaptive pressure regulation function, it significantly improves the comprehensive energy efficiency and adaptability of the equipment to working conditions.

For End Consumers

Our products offer exceptional cost-effectiveness, superior craftsmanship, and extended durability. With model options ranging from 0.8 tons to 12 tons (crawler, wheeled, or wheel-crawler excavators), we cater to diverse needs and provide customization options to suit your preferences.

For Distributors

We ensure top-quality assurance during the product warranty period. Additionally, we offer free advertising support in your country and accommodate customizations such as product colors and trademarks to strengthen your market presence.

Specification

Model | KN90-Y |

Engine Power | 46.3KW |

Maximum torque | 223.3-243.5N.m/1600rpm |

Max.travel speed | 30km/h |

Max. Grade ability | 30° |

Pump type | Variable pump x2 + Gear pump x2 |

Pump Pressure P1 P2 | 25Mpa |

Pump Flow rate P1 P2 | 132L/min |

Hydraulic Tank Capacity | 150L |

Fuel tank capacity | 150L |

Engine Fuel tank capacity | 12L |

Max. digging radius | 6787 mm |

Max. digging depth | 3323 mm |

Max. digging height | 7187 mm |

Max. dumping height | 5306 mm |

Packing & Shipping

Production Workshop

About Our Factory

Core Expertise

As an established earthmoving equipment manufacturer since 1995, we develop premium-grade wheeled excavators, crawler excavators, and compact haulers adhering to global operational benchmarks.

Global Reach

Our solutions serve clients across multiple continents through strategic partnerships, maintaining consistent presence in key industrial markets worldwide.

Product Portfolio

Wheeled Excavators: Versatile configurations for diverse terrain requirements

Crawler Excavators: Engineered for challenging environments with enhanced stability

Compact Haulers: Space-efficient material handling systems for restricted access zones

Quality Assurance

A specialized engineering team implements rigorous production protocols, integrating CE and ISO compliance standards at every manufacturing phase to ensure operational reliability and worksite safety.

Certification Commitment

All equipment meets internationally recognized certification requirements, validating performance durability and regulatory adherence.

Exhibition

Our Service

1. Positive Experiences We are committed to ensuring your experience with us is nothing but positive, standing firmly behind every product we sell. 2. Pre-Sale Service Feel free to contact us, whether or not we end up collaborating. You’ll gain valuable insights as we share our extensive experience in sales and production. Together, we can explore future developments in this field, helping both sides increase profitability and drive improvement. 3. Customized Services We take the time to carefully analyze customer requirements to recommend the most suitable machine. Based on production scale and technical specifications, we provide personalized suggestions and samples to ensure an optimal fit for your needs.

4. Sale Service We prioritize responsive and thoughtful communication with our customers. Our team goes above and beyond by offering venue recommendations, cost-saving strategies, and guidance on maximizing the value of our machines.

5. After-Sales Service Framework

1) Dual Support Channels

Domestic clients receive on-site assistance, while international clients access 24/7 remote support. Cross-border technical dispatch available for specialized requirements.

2) Comprehensive Warranty Program

Full component replacements under standard service protocols for qualifying scenarios during coverage periods.

3) Service Continuity Options

Seamless post-warranty service extensions with maintained response standards and technical specifications.

4) Continuous Improvement Cycle

Real-time service quality monitoring with customer feedback integration, driving systematic service optimization.

FAQ

Q: What is your core product range?

A: We engineer premium earthmoving equipment including wheeled excavators, crawler excavators, and compact haulers, offering versatile configurations for diverse operational requirements.

Q: Are factory inspections available?

A: Prospective partners are encouraged to schedule pre-arranged facility tours, demonstrating our manufacturing excellence and quality control processes firsthand.

Q: Are replacement components available?

A: Our dedicated parts division supplies genuine components engineered for seamless integration with all machinery in our product ecosystem.

Q: How is equipment reliability assured?

A: All units undergo multi-stage verification protocols aligned with global compliance certifications including CE and ISO, ensuring operational integrity and workplace safety.

Q: What post-purchase support exists?

A: Our technical support network delivers multi-channel assistance encompassing remote diagnostics and prioritized field service dispatch to maintain operational continuity.